🏚️ In the world of tile installation, ensuring longevity and durability is key. This is where Schluter-DITRA comes in, revolutionizing the way we approach tile underlayment. With its unique features and multi-functional capabilities, it stands out as a crucial component in any tile flooring project. Let’s dive into what makes Schluter DITRA an indispensable product for both professionals and DIY enthusiasts.

Understanding Schluter DITRA: The Revolutionary Tile Underlayment Product

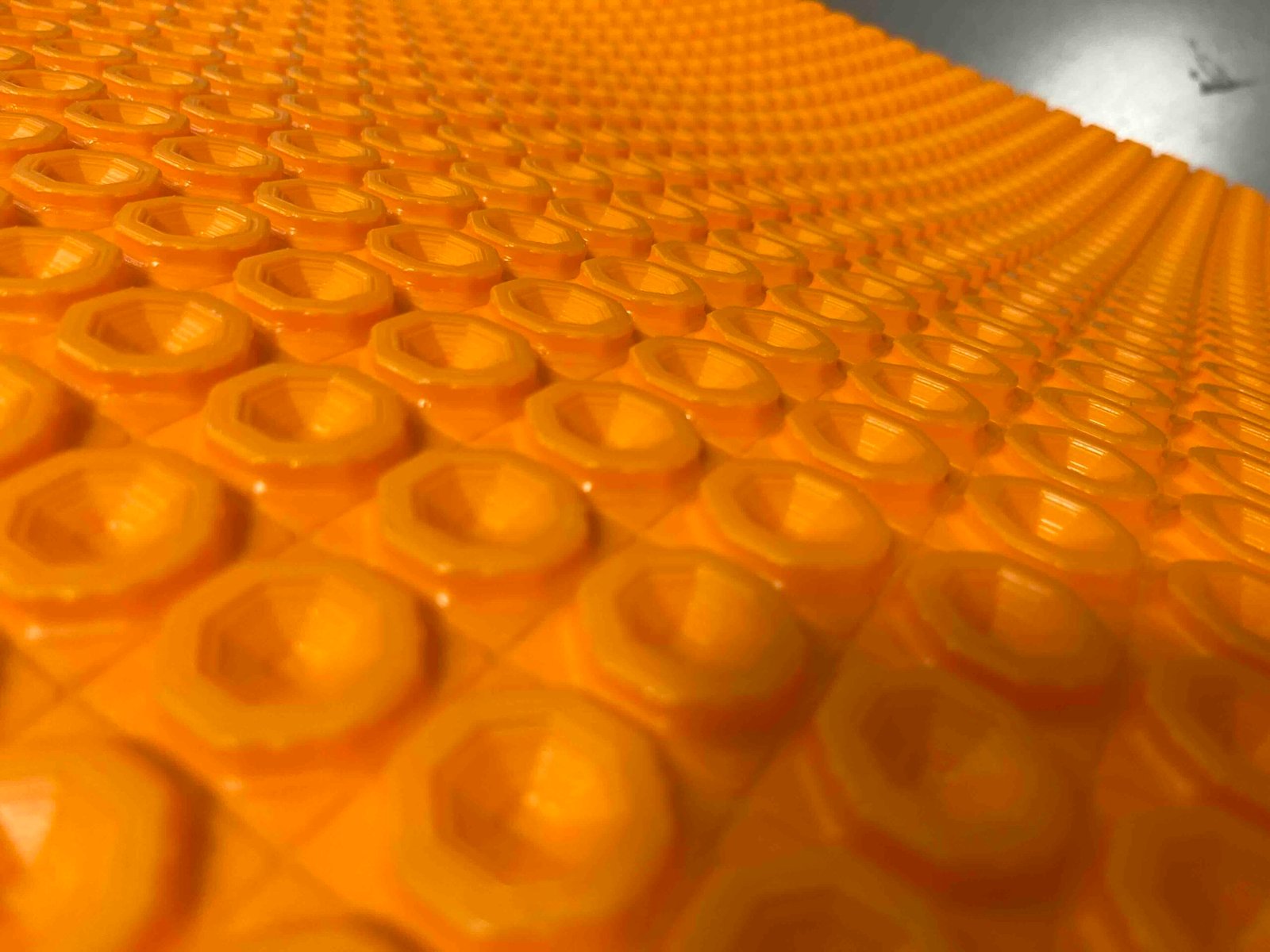

Schluter-DITRA is an uncoupling membrane specifically designed to address the challenges posed by common tile substrates. It’s crafted with a grid structure of cut-back cavities and features air release vents at the corners, making it a unique solution in the tile underlayment market.

Key Features and Functions

- Uncoupling: The core strength of DITRA lies in its uncoupling capability. The membrane’s open rib structure allows for independent movement between the tile and the substrate. This function is crucial as it prevents stress build-up in the tile covering that can lead to cracks and damage due to different rates of expansion and contraction between the floor and the tile in response to moisture, humidity, and temperature changes.

- Waterproofing: Tile coverings are not inherently waterproof, and water can seep through to the substrate. DITRA addresses this issue by providing reliable waterproofing, protecting moisture-sensitive substrates underneath the tile.

- Vapor Management: The design of DITRA facilitates effective vapor management. Its structure allows for excess moisture and vapor to escape from the substrate, making it suitable for use over concrete that’s less than 28 days old or on grade passing vapor.

- Load Distribution: DITRA ensures that load from the tile covering is transferred efficiently through column-like mortar structures formed in the membrane to the substrate. This ensures proper support for the tiles, especially in areas exposed to regular traffic.

Installation and Benefits

Installing DITRA involves bonding the membrane to the substrate using thin-set mortar. Tiles are then installed over the membrane using the thin-bed method, ensuring the cavities are filled with mortar for enhanced support. The cutback cavities and air release vents facilitate faster filling with fewer trowel passes.

The benefits of using Schluter-DITRA are multifaceted. It not only provides a solution to common substrate challenges like plywood, OSB, concrete, and gypsum but also enhances the overall durability and longevity of the tile installation. Its uncoupling, waterproofing, vapor management, and load distribution capabilities make it a universal underlayment choice for ceramic and stone tile.

Schluter-DITRA represents a significant advancement in tile underlayment technology. Its comprehensive approach to addressing common flooring challenges makes it a top choice for professionals and DIY enthusiasts alike. Whether you’re dealing with plywood, concrete, or any other common substrate, DITRA’s uncoupling, waterproofing, vapor management, and load distribution capabilities ensure a long-lasting, durable tile installation. Its user-friendly design also simplifies the installation process, making it accessible for a wide range of projects. With Schluter-DITRA, you can be confident that your tile flooring will stand the test of time, maintaining both its functionality and aesthetic appeal.

Comprehensive Guide to Installing Schluter-DITRA: Enhancing Your Tile Installation

When it comes to tile installation, choosing the right underlayment is crucial for ensuring a durable and long-lasting finish. Schluter-DITRA is a game-changer in this regard, providing not just a base for your tiles but also ensuring the longevity and integrity of your flooring. Here’s an in-depth look at how to install this innovative product correctly.

Preparation for Installation

- Review Installation Handbook: Before beginning, it’s essential to consult the Schluter-DITRA Installation Handbook for detailed guidelines and warranty information. Tailor your approach based on your specific project’s substrate, tile type, and other relevant factors.

- Prepare the Substrate: Ensure that the substrate is clean, even, and load-bearing. Sweep the floor to remove any debris, and make sure any leveling of the subfloor is done prior to installing DITRA. For wood substrates, check that subfloor panels are securely fastened.

- Clean and Cut the Matting: Use a utility knife or scissors to measure and cut the matting. Ensure any dust is cleaned from the substrate with a damp sponge.

Installing the Membrane

- Choosing the Right Mortar: Use Schluter ALL-SET modified thin-set mortar or Schluter FAST-SET rapid-setting modified thin-set mortar for bonding the matting to wood substrates. For concrete substrates, an unmodified thin-set mortar is suitable. Always verify the appropriate type of mortar for your specific substrate.

- Applying Mortar and Installing DITRA: Mix the mortar to a fluid consistency that can still hold a notch. Use the Schluter-DITRA-TROWEL (4.5mm square-notched) for application. Apply a thin layer of mortar with the flat side of the trowel for solid contact with the substrate, then comb additional mortar using the notched side. Place the DITRA (fleece side down) onto the mortar and embed it firmly using a float or the DITRA-ROLLER. Check for full contact between the fleece webbing and the thin-set mortar by lifting a corner of the membrane.

- Weight and Re-Embed: When using the DITRA-ROLLER, place a weight (not exceeding 75 pounds) on it to ensure proper embedding. Re-embed the membrane after checking for coverage.

Additional Tips for DITRA-XL and Waterproofing

- For DITRA-XL, use a trowel with a square notched design (one-quarter inch by one-quarter inch).

- To waterproof the floor, use Schluter-KERDI waterproofing accessories to seal seams and floor-to-wall transitions.

Tile Installation

- Preparing for Tile Setting: After installing DITRA, you can immediately set tiles using Schluter thin-set mortars or an unmodified thin-set mortar. Mark your tile layout with chalk lines, and apply hairspray to ensure the chalk doesn’t easily wipe off (this won’t act as a bond breaker).

- Filling and Setting: Fill the cutback cavities with thin-set mortar and comb additional mortar over the membrane using an appropriate notched trowel for your tile size. Back-buttering large-format tiles is recommended to ensure proper coverage. Embed the tiles solidly in the setting material.

By following these steps and paying close attention to the specific requirements outlined in the Schluter-DITRA Installation Handbook, you’ll be able to install your tile with the confidence that it’s resting on a solid, reliable base. Schluter-DITRA’s integration of uncoupling, waterproofing, vapor management, and support functions ensures a successful installation over common tile substrates, making your tiling project not just easier but also more durable. For any further queries, don’t hesitate to contact Schluter’s Customer Support Specialists, and for more information, visit their website or YouTube channel.

For more detailed information about Schluter-DITRA, its installation, and its wide range of applications, you can visit the official Schluter website at Schluter-DITRA. This resource provides in-depth insights, guidelines, and technical details about this innovative tile underlayment system.

Understanding the Mechanics Behind Schluter-DITRA’s Performance

To fully appreciate the capabilities of Schluter-DITRA as a tile underlayment system, it’s crucial to understand the dynamics of a tile assembly and how DITRA effectively manages the stresses within this assembly. A tile installation is a composite system comprising various layers, including underlayments, bonding mortars, and the tile itself. This system is subjected to different types of stresses, such as loading, temperature changes, and moisture content variations. These stresses generate compressive, tensile, and, most critically, shear stresses at the interfaces between the layers.

How Does DITRA Work?

- Stress Management: The primary role of DITRA is to manage and neutralize the shear stresses caused by differential movements between the substrate and the tile. This is achieved through its unique design that provides uncoupling (geometric flexibility) via an open rib structure. This structure allows for in-plane movement, effectively neutralizing differential movement stresses.

- Load Distribution: DITRA features column-like mortar structures formed in its cutback cavities. These columns transfer loads from the tile covering to the substrate. Mortar, known for its high compressive strength, renders DITRA virtually incompressible within the tile assembly without sacrificing the system’s load-distribution capabilities.

- Testing and Performance: The Tile Council of North America (TCNA) has conducted tests, including ASTM C627, to evaluate the performance of tile installation systems. DITRA has demonstrated remarkable performance under these tests, achieving a “heavy” rating, which is suitable for high-traffic and load-bearing areas like commercial kitchens, laboratories, and even outdoor decks.

- Flexural Strength and Stone Tile Installations: When it comes to natural stone, which often has lower flexural strength compared to ceramic tiles, the importance of DITRA becomes even more pronounced. Due to the inherent variability in the strength of natural stones (indicated by their veins, fissures, etc.), a more robust underlayment system like DITRA is crucial to distribute loads effectively and minimize the risk of cracking.

- Double-Layer Wood Floor Requirement: For installations involving natural stone over wood substrates, Schluter-Systems recommends a double-layer wood floor. This requirement stems from the lower flexural strength of most stone products compared to ceramic tiles and the need to mitigate the flexural stresses in the surface covering, which could lead to cracks in more brittle materials.

Conclusion

In summary, Schluter-DITRA’s effectiveness as a tile underlayment system lies in its ability to manage different types of stresses within a tile assembly. Its design allows for in-plane movement, mitigating shear stresses, and its structure ensures efficient load distribution. This makes DITRA an ideal choice for a wide range of tile installations, from ceramic to natural stone, ensuring durability and longevity even in high-stress environments. For detailed guidelines on specific installation scenarios, referring to Schluter’s comprehensive resources is always recommended.